Our 360° Facility

Materials Development

(Lexington, MA)

Small-Scale Materials Synthesis

In our labs, we can rapidly synthesize a wide range of Li-ion active materials in batches of a few grams to a few kilograms. Equipment available includes ball mills, high energy mills, muffle furnaces, tube furnaces, mechanical sieves, and etc.

In addition, a general purpose wet-chemistry lab is used for carrying out a small-scale wet synthesis of advanced anode and cathode active materials.

Materials Characterization

Materials characterization is carried out onsite using a wide range of custom-designed titrations as well as XRD, BET, PSD, KF, TGA, DSC, press density, and etc.

Additionally, CAMX Power is an industrial partner at Harvard University’s Center for Nanoscale Systems through its ClubNano™ program, giving us full access to a large suite of state-of-the-art tools for materials imaging and analysis including SEM, EDX, FIB, XPS, and etc.

Electrode and Cell Development

Small Cell Fabrication

We routinely fabricate more than 40 small coin cells every day as well as several single-layer pouch cells for a wide range of characterization tests.

A humidity-controlled laboratory (< 25% RH) houses benchtop equipment for slurry mixing (planetary centrifugal mixers), viscosity measurement, electrode sheet coating (single and double-sided), electrode drying in ductless hoods, and electrode calendering. Coin cells are assembled in Argon-filled gloveboxes.

High-performance coin cells and single-layer pouch cells can be fabricated with lithium metal, LTO, graphite, or silicon as the anode.

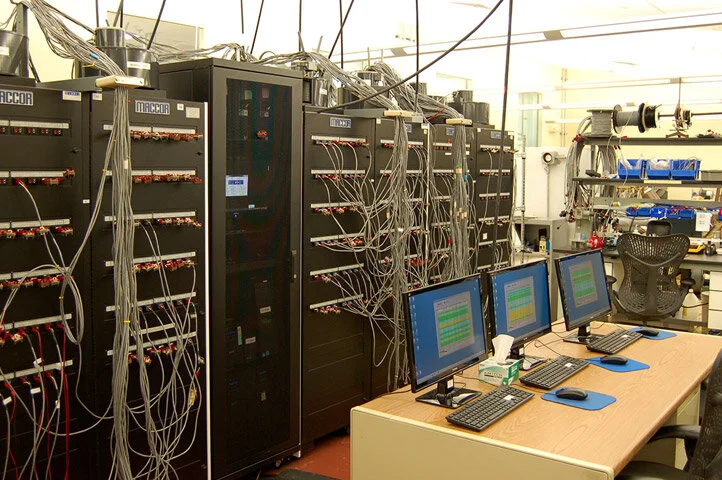

Electrochemical Characterization

With nearly 1000 testing channels in-house, we can test a wide range of Li-ion cells and battery packs for a variety of duty cycles over temperatures ranging from -40 to 85ºC.

Impedance spectroscopy and specialized potentiostatic/galvanostatic electrochemical techniques are used to evaluate electrochemical performance.

Cell Prototyping and Testing

Li-Ion Cell Prototyping

CAMX Power’s battery prototyping facility enables rapid assembly of cylindrical and prismatic Li-ion cells with a wide range of performance attributes.

The facility is equipped with a planetary slurry mixer with disperser, an electrode coater capable of fabricating double-sided patterned electrodes, a semi-automatic electrode winder capable of fabricating cylindrical and prismatic jelly rolls, electrode slitter, electrode calender, electrolyte filler, groover and crimper, and several types of tab welding machines.

Most of the equipment is housed in a dry room rated for -40°C dew point, which enables the handling of moisture-sensitive materials and electrodes.

Abuse Characterization

At CAMX Power, the abuse tolerance of multi-Ah Li-ion cells is characterized using a wide range of standardized tests including nail penetration, hot box, impact, round-bar crush, parallel-plate crush, and etc.

All of these measurements are enabled by highly-instrumented equipment that was designed and custom-built in-house.

Our equipment allows us to obtain an unprecedented level of information of cell behavior in these tests.

Pack Prototyping

CAMX Power’s cell prototyping equipment outlined enable robust pack prototypes to be developed which can easily be translated to scaled-up manufacturing.

Materials Scale Up

(Rowley, MA)

Pilot Scale Process Development

In our pilot plant, up to 50 t/year of cathode materials can be synthesized using a solid-state synthesis process. The plant is equipped for precursor blending; calcination under controlled environment; spray drying; particle classification; and dust collection.

A Noritake roller hearth kiln was installed and commissioned in 2016.